Rub testing plays a crucial role in determining how well materials stand up to everyday wear, friction, and handling. Whether used on fabrics, coatings, packaging, or high-tech surfaces, this testing method helps manufacturers understand durability long before a product reaches consumers. By exploring what is rub testing and why it matters, you can gain valuable insight into how quality, performance, and reliability are measured across a wide range of industries.

The Science Behind Rub Testing: How It Works

Defining Rub Testing: A Deep Dive into the Process

So, what is rub testing? At its core, rub testing is a controlled method used to measure how resistant a material is to wear caused by friction. It is commonly applied to textiles, coatings, packaging, printed surfaces, and other materials that are frequently touched, rubbed, or moved against other objects.

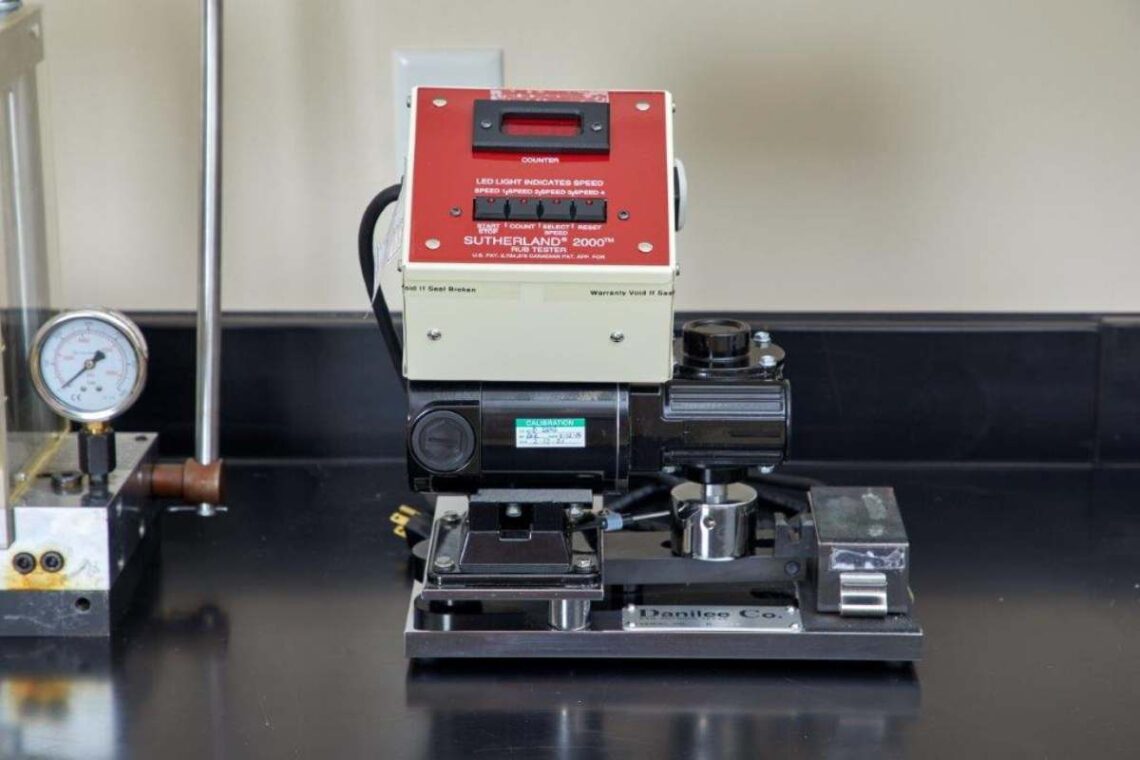

In a typical rub test, a sample is placed in a testing machine that repeatedly moves an abrasive material across its surface. This motion simulates real-world use, such as fabric rubbing against a seat, a label contacting another box in shipping, or a touchscreen being swiped again and again. By recreating these motions in a standardized way, rub testing allows manufacturers to predict how a product will hold up in everyday conditions.

The goal is not just to see if something will wear out, but to understand how fast it will happen and under what conditions. That insight supports better design decisions and higher product reliability.

The Key Components of Rub Testing: Materials and Methods

The reliability of rub testing depends on three main elements: the sample material, the abrasive medium, and the test method.

- Sample material: This could be fabric, printed packaging, painted panels, coated plastics, or any other surface that needs to be evaluated for wear.

- Abrasive medium: This can range from a simple dry cloth to felt pads, rubber, or even sandpaper, depending on how aggressive the test needs to be.

- Test method: Different standardized methods exist, such as the Martindale rub test or Taber abrasion test. Each has specific procedures for how the abrasive moves, how much pressure is applied, and how many cycles are run.

Other variables include the speed of movement, the environment (such as humidity and temperature), and whether the test is performed dry or with added liquids, like water or cleaning solutions. All of these are tightly controlled so that test results are consistent, measurable, and comparable over time.

Interpreting Rub Testing Results: What Do They Really Mean?

Rub test results are more than just pass or fail. They help answer detailed questions about performance. For example:

- Does the color rub off after a certain number of cycles?

- Does the surface become dull, scratched, or fuzzy?

- Is there visible loss of coating, print, or texture?

Results are often rated on scales, such as levels of colorfastness or degrees of wear. These ratings can be compared against industry standards, internal specifications, or competing products. For a textile manufacturer, failing to meet a minimum rub rating might mean changing the dyeing process. For a packaging brand, poor rub resistance might signal the need for a stronger overprint varnish.

Understanding what the numbers really mean allows teams to improve materials, adjust production processes, and ensure that the final product meets both functional and aesthetic expectations.

Why Rub Testing Is Crucial for Your Products

Ensuring Quality Control: The Risk of Skipping Rub Testing

Skipping rub testing introduces serious risks. Without it, products may look fine during development but fail quickly once in the hands of customers. Colors might transfer onto other surfaces, coatings may wear off, or printed information could become unreadable.

These failures can lead to product returns, warranty claims, and negative reviews that harm brand reputation. In some sectors, inadequate wear resistance can even create safety concerns. Rub testing serves as an early warning system, catching weaknesses before products reach the market. It is a key part of quality control that protects both the consumer and the brand.

Enhancing Durability: How Rub Testing Extends Product Lifespan

Consumers increasingly expect their purchases to last. Rub testing supports durability by revealing how a product will behave over time and under repeated use. When results show weak points, manufacturers can experiment with stronger inks, improved coatings, different fabrics, or alternative finishes.

Over time, this leads to products that hold their color, resist scuffing, and maintain their appearance longer. For example, a clothing brand that uses rub testing to refine its fabrics can confidently promote garments as colorfast and long-wearing. In an era where sustainability matters, building longer-lasting products aligns with customer values and reduces waste.

Industry Standards and Regulations: The Legal Necessity of Rub Testing

In many industries, rub testing is not optional. It is required by standards and regulations that define acceptable levels of wear and colorfastness. For textiles, standards like ISO 105 or ASTM D4966 outline how rub tests should be conducted. Other sectors, such as automotive or consumer goods, have their own relevant guidelines.

Compliance with these standards is often necessary to sell products in certain markets, secure certifications, or meet contracts with major retailers and manufacturers. Failing to meet these requirements can result in product rejections, fines, or mandatory redesigns. This makes rub testing both a quality tool and a legal safeguard.

Applications of Rub Testing Across Different Industries

From Textiles to Automobiles: Where Rub Testing Is Used

Once you understand what rub testing is, it is easy to see why it shows up in so many industries.

- Textiles and apparel: Used to check if dyes rub off onto other surfaces, such as furniture, car seats, or other clothing.

- Furniture and upholstery: Ensures that fabrics and leathers withstand daily friction without excessive wear.

- Automotive interiors: Evaluates seat fabrics, dashboard coatings, and trim pieces that see frequent contact.

- Packaging and labels: Confirms that printed graphics and text do not smudge or rub away during shipping and handling.

- Flooring and coatings: Checks the resistance of finishes exposed to foot traffic or physical contact.

In each case, rub testing helps ensure that materials can handle their intended use without rapid deterioration.

The Role of Rub Testing in Consumer Goods: Meeting Expectations

In consumer products, customers often judge quality by how well an item holds up over time. Rub testing helps manufacturers meet those expectations.

Kitchen textiles, toys, phone cases, luggage, and more all undergo friction in daily life. When manufacturers use rub testing, they can adjust materials and finishes to deliver products that resist fading, scratching, and surface breakdown. Some companies even highlight test results in their marketing to demonstrate performance and build trust.

In a crowded market, being able to show that your product has been tested and proven to last can provide a valuable competitive edge.

Innovative Uses of Rub Testing in High-Tech Industries

High-tech fields are finding new ways to apply rub testing to modern materials and devices.

- Electronics: Touchscreens, buttons, and device casings need to withstand constant touching, swiping, or being carried in pockets and bags.

- Aerospace: Coatings on interior and exterior components must endure extreme conditions while retaining protective and aesthetic properties.

- Medical devices: Surfaces that come into contact with skin or are frequently cleaned must resist wear without compromising safety.

By integrating rub testing into their quality programs, high-tech industries ensure their products remain reliable even in demanding environments.

Future Trends in Rub Testing: What Lies Ahead?

Advancements in Technology: How AI and Automation Are Changing Rub Testing

As technology advances, rub testing is becoming more precise and efficient. Automated test machines can run consistent cycles with minimal human input, reducing errors and improving repeatability. AI-driven software can analyze large volumes of test data, identifying patterns and predicting performance outcomes faster than manual methods.

These tools help manufacturers make quicker decisions, refine materials more effectively, and shorten product development cycles, all while maintaining rigorous quality standards.

Environmental Considerations: The Shift Towards Sustainable Testing Practices

Sustainability is shaping how companies think about testing. Traditional testing methods can use significant materials and create waste. In response, many organizations are exploring greener approaches, such as:

- Using more environmentally friendly abrasives

- Optimizing test protocols to minimize samples and waste

- Developing recyclable or biodegradable test materials

At the same time, rub testing supports sustainability by helping companies create longer-lasting products, which reduces the frequency of replacement and minimizes environmental impact.

The Globalization of Rub Testing: Navigating International Standards

As businesses sell into more markets worldwide, they face multiple international standards for rub testing. Requirements may vary from one region to another, making compliance more complex.

To stay competitive, companies must stay informed about global testing standards and maintain flexible testing programs that can meet diverse regulatory expectations. Collaboration with international labs, participation in standards organizations, and ongoing training are all becoming more important for quality teams that operate in global markets.